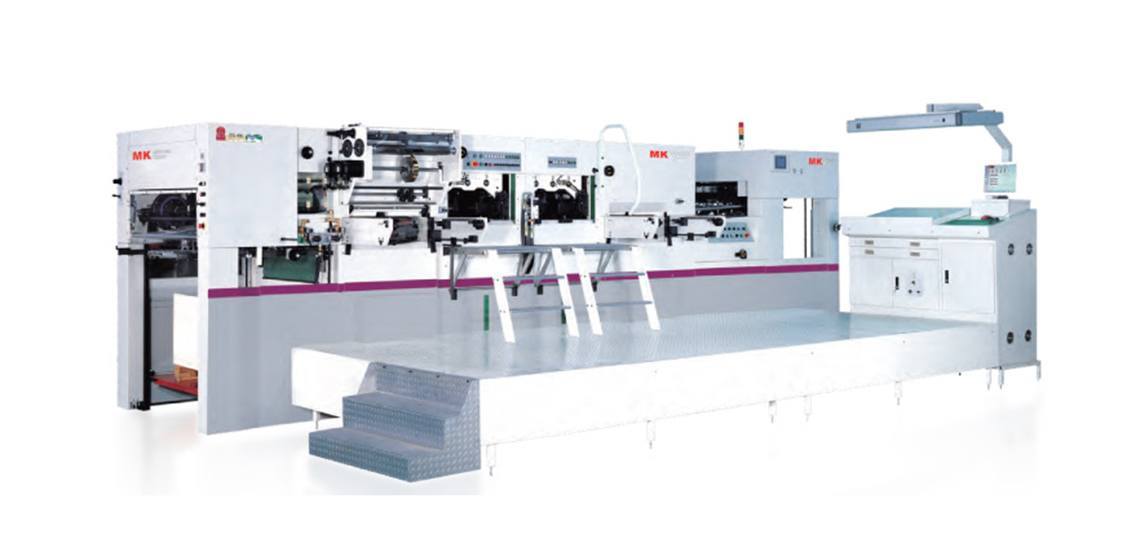

THE WORLDS FIRST 6 PROCESS IN ONE PRINT FINISHING MACHINE

Duopress Machine Model 920SS

First choice for high-end cigarette packages, Special creation for the top-quality packaging and your demand

Feeder

- Strong suction head, 4 lifting and 5 forwarding suction cups. The suction head can be adjusted to the angle for various stock quality.

- When the sheets arrive at the front lays, a speed control system guarantees the precise location of the sheet.

- Vernier calibration is adjusted manually for accuracy and ease of operation

- The side lays have a pull or push facility which can be adjusted easily by one screw

- Improved conveying belt

Platen Press Section

- Synchronized energy transferring

- Servo motor for pressure adjustment

- 3mm + 1.2mm combined type lower plate. The bottom plate will have a Vernier calibration system which can be used to adjust the plate in two directions.

- The gripper bar is built from specially treated ultra-hard aluminum alloy. To improve the high register accuracy, the gripper bars uses paten designs with an adjusting mechanism.

- Main drive chains are imported and are a specially strengthened chain design. The stress resistance of the chain is increased by 46% which improves stability and accuracy of the machine, it also improves the longevity of chains’ life span.

- Foil section are equipped with 20 individual heated zones. The heating controls are imported and guarantees a long life span.

- Tool less operation made possible by our pneumatic locking device.

Key advantages

- Overcome the constraint of one main platen press section on normal foil-stamping machine. This Two main platen press section machine can produce any two combinations from foil-stamping, embossing, and die-cutting in one pass.

- Two time stamping process or stamping plus die-cutting can be finished by one time sheet fed, this will improve efficiency dramatically, reduce labor cost and scrap rate.

Contact us for more information

SPECIFICATIONS

See what the 960SS can do

| Max sheet size | 920mm x 650mm |

|---|---|

| Min sheet size | 360mm x 320mm |

| Max die cutting size | 910mm x 630mm |

| Stock range | 0.1-2mm (paper) |

| Max working Force | 200T |

| Max working speed | 5000 s/h die-cutting / 5000s/h stamping |

| Heating system | 20 heating zones / 40 ~ 180C |